Overview of Facility

Fabricate Steel Structure at its state- of- art plant spread over 79,000 square meter at Jejuri near Pune, India.

Built Up Machines

- CNC Based control with 8 torch Oxy- fuel gas straight cutting and 1 torch with profile cutting

- Profile Cutting CNC Machine

- Beam Assembly Machine

- SAW Welding Machine

Hot-Rolled Machines

- CNC Beam Drill Line

- High Speed Flat Drill and Burn

- High Speed Flat Punch and Burn

- Robotic Oxy – Fuel CNC coping Machine

Inspection & Trial Assembly

Indiana is committed to quality products to meet customer’s requirements to test the product at shop before It leaves for erection to ensure the quality by performing Trial Assembly at different levels as per customer specifications.

Testing Facilities

Dye Penetration Test (DPT)

DPT also called liquid penetrant inspection (LPI) or penetrant testing (PT), is a widely used lowcost inspection method to locate surface-breaking defects in all non-porous materials (metals, plastics or ceramics).

Ultrasonic Test (UT)

UT, is a family of non-destructive testing techniques based on the propagation of ultrasonic waves in the object or material tested.

A common example is ultrasonic thickness measurement, which tests the thickness of the test objects, for example, to monitor pipework corrosion.

Magnetic Particle Test (MPT)

MPT, is a non-destructive testing (NDT) process for detecting surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt and some of their alloys. The zprocess puts a magnetic field into the part.

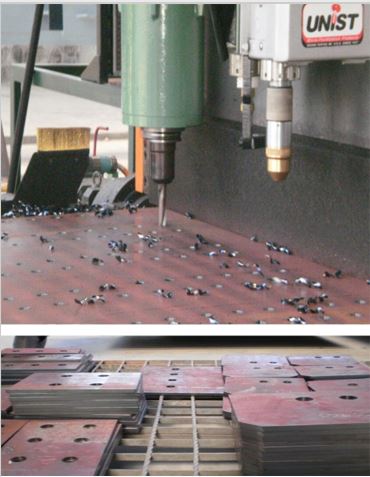

CNC Plate Processing Machine

- CNC marking through the scriber as required by the customer.

- CNC drilling through automated measurements as per the NC files.

- CNC cutting with auto measurements (plasma upto 40mm and above 40mm oxy fuel cutting).

- Automated dumping of components on the collection pallets.

- Machine can drill with HSS and carbide drills up to 75mm.

- Can hold 8 different dia drill bits.

- Raw material of 2500mm wide and 12mtrs long can be loaded.

- SDS system used to read CNC files from detailing software. Can import DSTV files.

- Min of 6mm plate and maximum of 100mm can be loaded for processing any

Process in the CNC Saw Cutting Machine

- CNC Band Saw Machine is used to cut beams ,channels angles, tubes and pipes automatically without having any manual measurements.

- This machine can cut materials with beam depth of 1250mmx610mm flange width x20,000mm long.

- Surface finish for the cut area is as good as mill finish.

- BSM has Accumeasure which is used to measure beam and as well to mark the beams with scriber.

- The machine can swing on either side to cut the right hand and left hand miter up to 45 degree.

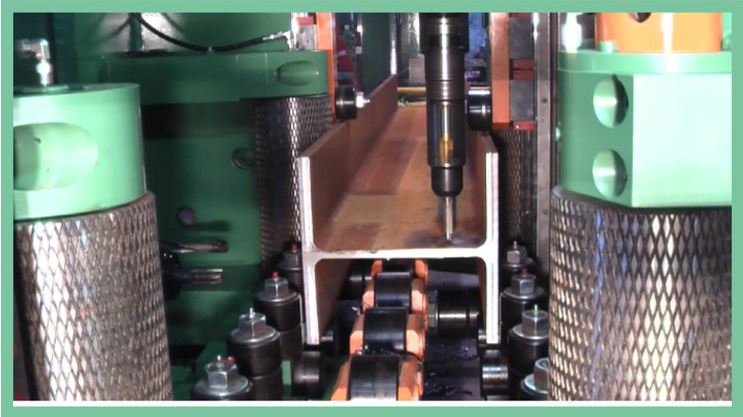

Beam Drilling on CNC Drilling Machine

- CNC Band Saw Machine is used to cut beams ,channels angles, tubes and pipes automatically without having any manual measurements.

- This machine can cut materials with beam depth of 1250mmx610mm flange width x20,000mm long.

- Surface finish for the cut area is as good as mill finish.

- BSM has Accumeasure which is used to measure beam and as well to mark the beams with scriber.

- The machine can swing on either side to cut the right hand and left hand miter up to 45 degree.